The PrintLock is a 3d printed lightweight weblock with integrated soft shackle for low tensioned lines. With 44g it's probably the lightest weblock with connector with easily adjustable webbing length. It is suited for 25mm webbings that are up to 3mm thick. Print your own weblock, instructions are on ThingiVerse!

Stay tuned for the next version. It's gonna be lighter, stronger, better and might have a soft release function.

Motivation

I have a nice travel slackline setup by Elephant Slacklines but the two shackles and two chainlinks are a bit heavy (and the treepro a bit useless). I mostly rigged the line as a rodeo but got tired of adjusting the chainlink for the right line lengths so I used a weblock and shackle to rig the line with hand tension. Both solutions made the kit quite heavy. Furthermore I rigged longer rodeos with a weblock and shackle but the concentrated mass of around 550g was noticeable while surfing.

After testing the Slacktivity Traveler set I wanted to print their weblock which they kindly published on Thingiverse. Sadly it's only compatible to 20mm lines because the shackle is too small for 25mm lines. So I decided to design my own.

Design

I quickly realized the reasoning for Slacktivity to use 20mm: A shackle big enough for 25mm would be detrimental to make a kit light and 20mm webbing is also lighter than 25mm webbing. But being stuck with 25mm webbings I needed another solution. At that time I produced my first soft shackles and was flabbergasted by their almost non existent weight. So I combined the Slacktivity design with my wish to replace all metal shackles with softies.

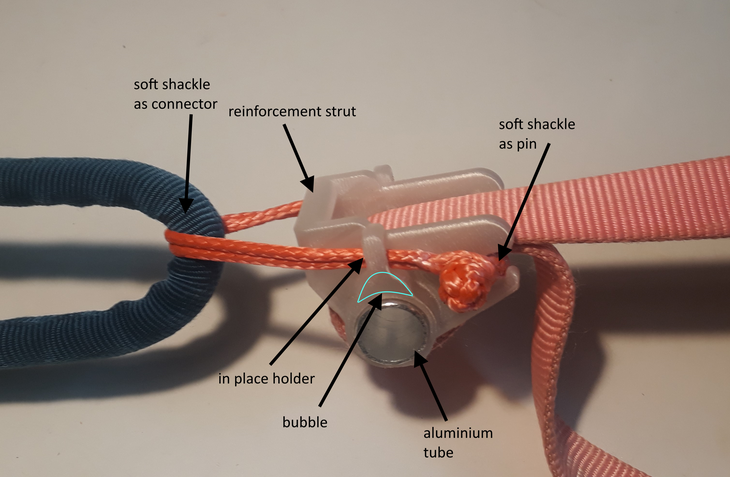

So I tried to wrap a weblock with a soft shackle. Using the soft shackle as "pin" and connector makes it light as a feather at 44g. The idea with the aluminium tube as diverter is stolen from Slacktivity. The small "bubble" on top the aluminium tube is important to make the system stable. When it is too high or too low the weblock flips. The small struts are to hold the soft shackle in place.

Breaktests

With my first kind of working PrintLocks I did some qualitative breaktests with my big pulley system outside. These showed me the weaknesses of the weblock. The soft shackle compresses the walls and they break because of too much bending momentum at the root. The positive side about the test was that the weblock breaks but doesn't fail completely and still holds the line. This version was already good enough for rodeolining although with only a tiny safety factor.

So my next iteration got a strut at the back to minimize the bending. I went to Slacktivity HQ and got some sweet PinkTube Type C (the old batch with the right back up length) and Sam made some breaktests for me. The weblock with 5mm walls broke at 2.8kN and the 7mm version at 4.4kN. Again, the weblocks didn't fail completely. The 3mm soft shackle broke at 17kN (and the 6mm at 72kN, so super good enough for highlining🥳)

Flaws of Version 1

Depending on the webbing thickness the system is instable. When the webbing is too thick the weblock flips forward until the reinforcement strut stops the rotation. The weblock is still working. When the webbing is too thin the weblock is flipping backwards which can end in breaking of the struts to hold the soft shackle in place. After this the bending moment of the walls increases drastically which can end in failure. This never happened for the intended use case of rodeo lining. But we tested the limits of "low tensioned" lines with a 70m and a lot of sag line and a 15m long and 1m sag line. In both cases the weblock broke only after some while.

This problem is caused by the different points of attack of the line. The thicker the webbing the higher point of attack of the force is. When it is higher than the softshackle the weblock flips. Vice versa with thin webbings. This could be solved by printing different weblocks for different webbing thicknesses. But to be honest who wants to carry multiple weblocks around just to have the right one ready to rig a specific webbing?

The weblock needs support while printing. First this makes a lot of work to post process, remove them and smoothen the surface. Second it damages your soft shackle. Unless you put a lot of work in postprocessing there will be some small and sharp rests of the support in the pin holes. They pull out single dyneema fibers which damages the soft shackle over time. The soft shackle will be still strong enough for a long time but it should be retired at one point.

The weblock is a bit hard to handle. You have to hold the weblock in place while inserting the webbing. Otherwise the soft shackle will slip out of it and you can't put it through the webbing. Also the two strands of the button knot soft shackle are sometimes a bit confusing.

Second Version

The second version is currently under development and needs some more tweaks and tests but it will feature:

- No flipping of the weblock

- Higher strength to weight ratio

- Improved soft shackle

- No supports for printing

- Easier pretensioning